I-Teknic yinkokeli yehlabathi kwi-die casting, kunye nabathengi ukusuka kwiinkampani ezinkulu zokuvelisa izixhobo ukuya kwishishini leemoto ukusuka kwingcamango yoyilo, kwimveliso kunye nokupakishwa.

Sinikezela nge-zinc die casting ukusuka kuyilo lokungunda kunye novavanyo, ukuya kwimveliso yecandelo le-zinc, ukugqiba, kunye nokupakishwa ukusuka kwiinkcukacha zoyilo oluntsonkothileyo kwaye zijike zibe yimveliso egqityiweyo.

I-Teknic ikhokela iinkampani zokuphosa i-zinc kwiminyaka eyi-10.Ukusukela ekusekweni kwayo, siye savela saba yinkokeli ekumgangatho wehlabathi sisebenzisa itekhnoloji kunye neengcali ezinezakhono zokwenza izinto ezikumgangatho ophezulu.Sigxila kumgangatho kunye nokusombulula iingxaki e-China.isiseko kwiziko lokuvelisa iZinc Molding.

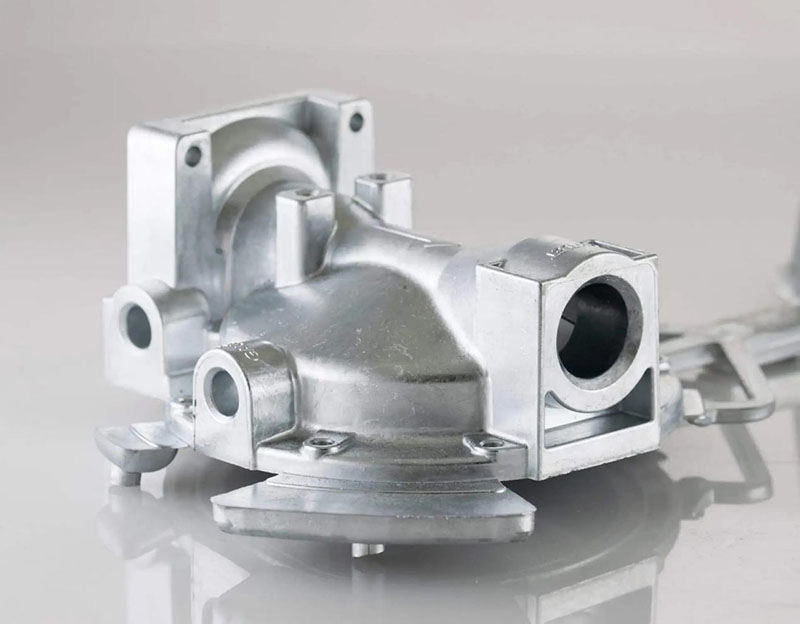

Iimilo ezintsonkothileyo kunye nokunyamezelwa okuqinileyo

I-Zinc die casting ivelisa i-multi-cavity, iimilo eziyinkimbinkimbi kunye nokunyamezela okusondeleyo kunezinye iinkqubo ezininzi zemveliso.Ukongeza ekuveliseni imitsi yevolyum ephezulu yamalungu aphantse afane, ivelisa ubushushu oburhabaxa kwaye inxibe iindawo ezixhathisayo ezinomgangatho ozinzileyo, ngelixa igcina ukunyamezelana okusondele kakhulu.

Inkqubo yokuphosa ukufa inika abayili ithuba lokulondoloza iindleko ngokuhlanganisa amacandelo abe yi-net-shape die casting.Ke ngoko, ukuphelisa imisebenzi yesibini efana noomatshini.Ii-zinc die castings ziyilwe ngempumelelo njengeebheringi (ukuphelisa ialloys zobhedu), iirivets, kwaye zinokuphoswa ngemicu.Ngenxa yolu ncedo, i-die castings ifumaneka kumashishini ahlukeneyo abandakanya iimoto, i-hardware yokwakha, i-electronics, iimpahla zemidlalo, njl.

Kufuneka kuqatshelwe ukuba ukunyamezela kwemigangatho yoshishino kunokuhlangatyezwa kunye / okanye kugqithwe, ukuba kuyimfuneko ekuyilweni kwenxalenye.Nangona kunjalo, zininzi izinto ekufuneka ziqwalaselwe, ezinje;ubume bendawo, apho uphawu lubekwe ngaphakathi kwesixhobo, ithini indawo yayo nezinye iimpawu zenxalenye kwaye ukuba ulinganisa ngapha komgca wokwahlulahlula.Xa kuqwalaselwa ubomi besixhobo kunye neendleko, yeyona ndlela ilungileyo yokuvumela ukunyamezelana okunesisa kunye nedrafti kwiindawo ezinomfaneleko omncinci, ifom okanye umsebenzi kunye nokuqinisa ukunyamezela kuphela kwiindawo apho kuyimfuneko.

I-Zine yethu ye-die cast casting ububanzi ukusuka kwiitoni ezili-100 ukuya kwi-300 yeetoni, ivelisa i-zinc die casting components zeenkqubo zokuvelisa umthamo ophantsi okanye ophezulu.Sinokwenza igumbi le-zinc elishushu lokufa liphosa, i-aluminium-zinc eshushu okanye igumbi elibandayo loxinzelelo oluphezulu lokufa, kunye ne-aluminium die casting.Ukujongwa kwenkqubo, umboniso wecala lokushicilela, iirobhothi, ukulinganisa ukuhamba, izixhobo ezingapheliyo kunye neenkqubo zokulondolozwa kwezixhobo zisetyenziselwa ukwandisa ubomi besixhobo, ukonga iindleko, ixesha, kunye nokubonelela ngokufa okusemgangathweni ophezulu.Ukusuka kwinxalenye yokukhulelwa kunye neprototyping ecokisekileyo, ukudibanisa imveliso egqityiweyo.

Zinc Alloys

Siyinkokeli kwimveliso ye-die cast e-China.I-Metallurgists yethu eqeqeshiweyo iqinisekisa ukuba zonke ii-alloys zihlangabezana neenkcukacha ngokuhlalutya rhoqo kweekhemikhali kunye nomzimba.

Iialloys zethu ziquka:

Zinc: Zamak 3, 5, and 7.

I-Zinc-Aluminium: ZA-8, ZA-12, kunye ne-ZA-27.

I-zinc alloys zilula kuxinzelelo oluphezulu lwe-diecast.Banikezela nge-ductility ephezulu, amandla empembelelo, kwaye banokucolwa ngokulula.I-zinc alloys ine-melting point ephantsi kune-aluminium enokunceda ekuphuculeni ubomi bokufa.

I-ZA i-alloys zizinto zokuphosa ezisekelwe kwi-zinc ezinomxholo ophezulu we-aluminium kune-alloys ye-zinc eqhelekileyo.Ezi alloys zineempawu eziphezulu zamandla kunye nobunzima obuphezulu kunye neempawu zokuthwala kakuhle.

Uvavanyo lweZinc Mold Flow

I-Teknic isebenzisa itekhnoloji yokulinganisa i-CAM eyaziwayo kumazwe ngamazwe ukukhulisa uyilo lwesixhobo kunye nomgangatho wokuphosa we-zinc.

Izakhono zokulinganisa i-CAM zibonelela ngokuqonda okungcono kokuzaliswa kwe-zinc injection mold, ukuqina, iimpawu zomatshini, uxinzelelo lwe-thermal kunye nokuphazamiseka.Imenyu eqhutywa ngokupheleleyo kunye nemodeli edibeneyo edibeneyo, i-CASD interfaces, kunye nedatha ebanzi, i-CAM ibonelela ngesisombululo esipheleleyo soyilo, imveliso, kunye namasebe asemgangathweni.

Steel Isitofu Mold Castings

CNC Machining kunye Hog-outs

Ngqo Metal Laser Sintering (DMLS)

P-20 izixhobo

I-ZINC SURFACE UKUQEDA

I-Teknic iya kulawula iimfuno zokugqiba umthengi ukuqinisekisa ukuba iinxalenye zihlangabezana neenkcukacha ngexesha elifanelekileyo kunye neendleko ezifanelekileyo.

Ukugqiba kwethu umgangatho we-zinc kubandakanya:

Ukwambathisa ngomgubo (usetyenziso lombane)

Ipeyinti emanzi

Chromate

I-E-Coat

I-Nickel engenambane

IChrome

UkuHlolwa kweSilika kunye neStenciling

EMI/RFI Shielding

i-Surface Conditioning (ukudubula kunye nokuqhushumba kweentsimbi)